- Standard steel

- Stainless steel

1.4301 (AISI 304) or 1.4404 (AISI 316),

1.4571 (AISI 316Ti) etc. - Aluminium

- GRP Glas Fibre Reinforced Plastic

- Other materials on request

- Liquid coating in all RAL und NCS colourways

with food safety compliance | FDA compliance - Powder coating in all RAL und NCS colourways

with food safety compliance | FDA compliance - Glass bead blasting

- Electropolished

- Mordants | passivate

- Brushed

- Anodized

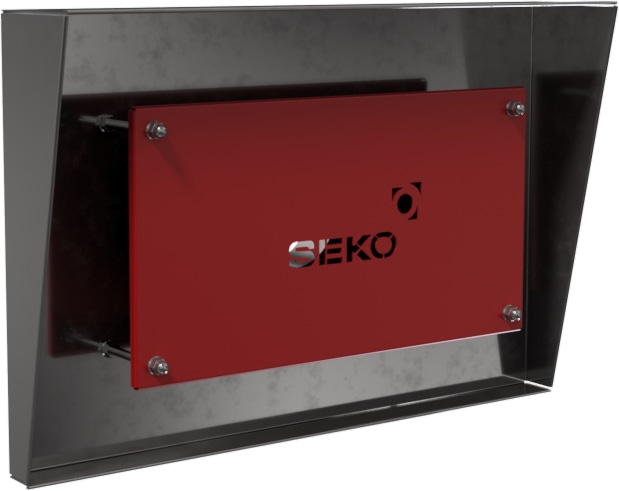

Our filter equipment is available on request in versions which are shock pressure resistant or pressure resistant up to 11 bar absolute (10bar [overload pressure]) for all Ex zones (zone 20, zone 21, zone 22, zone 0, zone 1, zone 2).

If necessary or desired, we can equip the dust extraction equipment with the corresponding explosion protection mechanisms:

- Bursting disk | Rupture disk

- Q-Pipe

- Q-Box

- Check-Valve

- Relief-Valve

- Flame extinguisher equipment

(H²O, CO2, etc.) - Spark detection

- Rotary valve in a shock-pressure-resistant, ignition-resistant configuration

- Potential equalization

- Antistatic filter material

- ATEX compliant plant components

Client Specific

In addition to the development and manufacture of dust extraction equipment, SEKO also offer a full range of plant engineering:

Whether you need discharge or conveyance equipment, steel constructions or customised constructions – we will cooperate with you to find the optimum solution.

We will be happy to work with you as your central point of contact for your complete plant engineering solution and will ensure that all individual components are optimally calibrated for joint functioning.

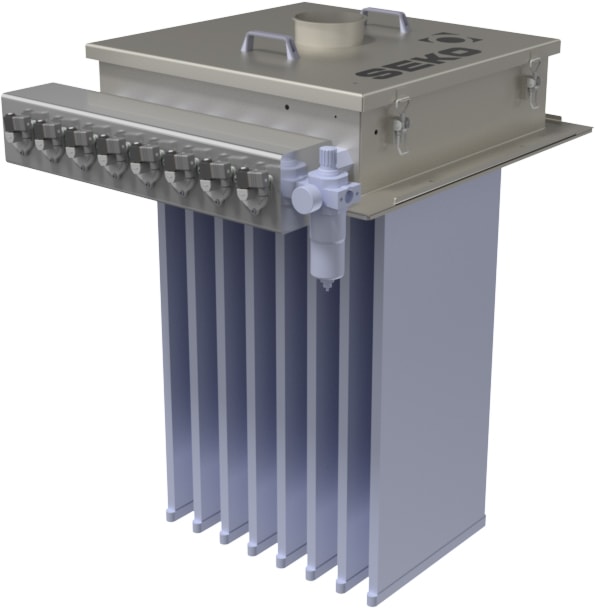

CVC – Central Vacuum Cleaning System

Cleanliness is the top priority of many businesses. SEKO can support you in this aim, with energy-saving Central Vacuum Cleaning Systems specially tailored to your needs. It doesn’t matter whether you require three suction points or three hundred: our equipment is fully scalable to meet your needs.

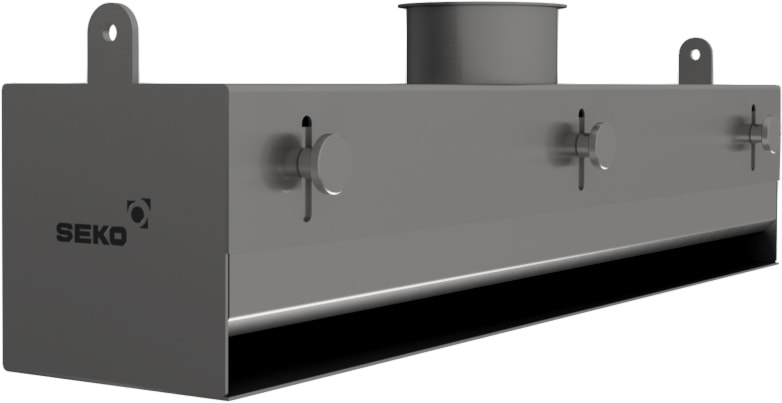

Blend Selector

SEKO’s Blend Selector, specially developed for the tobacco industry and other industrial sectors, allows you to connect each feeder with each maker – with impressively short set-up times.

The connections are simple and can be set up quickly and easily and monitored using a connection control.

We can, of course, also supply a suitable accompanying steel construction.

Piping | Conveyor piping | Pneumatic conveyance

The following configuration options are available:

- Pressure transport

- Suction transport using rotary piston blowers, side channel blowers, fans

- Standard steel in all RAL und NCS colourways food-safe certification | FDA compliant

- Stainless steel

- Aluminium

- Spiral duct

- Pipe systems with clamping ring or flange design

- Special pipe connectors to ensure minimum product degradation

Turnkey systems

Whether you are planning a new production plant or would like to modernize existing equipment: The most important thing you’ll need is a reliable partner with the experience and expertise to support you.

SEKO offers turnkey solutions for innovative plant technology – from collection, through filtration, to a central delivery point, for example using big bag stations or filling C48 boxes.