We offer replacement parts in all desired configurations, by design, model and specs – for other manufacturers’ equipment, too.

Filter bags | Bag frames

We supply filter bags in a variety of different needle felts and fabrics, with USGC category test certification (new dust category L + M) as needed, in:

Polyester, polypropylene, Dolanit, mixed polyester-Dolanit felt, Aramid/Nomex, polyamide, P84, Ryton, PTFE, polyacrylonitrile, nylon, ATEX antistatic polyester-silk weave, cotton.

- Singed

- Smoothed

- Calendared

- Hydrophobic / oleophobic (oil, dirt and damp repellent)

- Siliconized

- Acid and hydrolysis protection

- PTFE surface coating

- ePTFE membrane

- Conductive (antistatic) with and without EXAM certification

- Spark suppressant foam coating

- Flame retardant

- Microfibers

- BIA tested

- Food-safe certification

- Standard steel galvanized or powder coated

- Stainless steel 1,4301 (AISI 304) or 1,4404 (AISI 316)

- With or without venturi in the materials steel, aluminium and stainless steel

- Designs with untreated or purified gas side attachment

Filter tubes | Support cages

We supply filter tubes in a variety of different needle felts and fabrics, with USGC category test certification (new dust category L + M) as needed, in:

Polyester, polypropylene, Dolanit, mixed polyester-Dolanit felt, Aramid/Nomex, polyamide, P84, Ryton, PTFE, polyacrylonitrile, nylon, ATEX antistatic polyester-silk weave, cotton.

- Singed

- Smoothed

- Calendared

- Hydrophobic / oleophobic (oil, dirt and damp repellent)

- Siliconized

- Acid and hydrolysis protection

- PTFE surface coating

- ePTFE membrane

- Conductive (antistatic) with and without EXAM certification

- Spark suppressant foam coating

- Flame retardant

- Microfibers

- BIA tested

- Food-safe certification

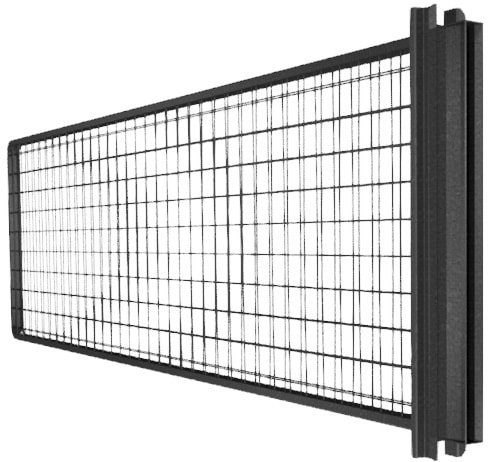

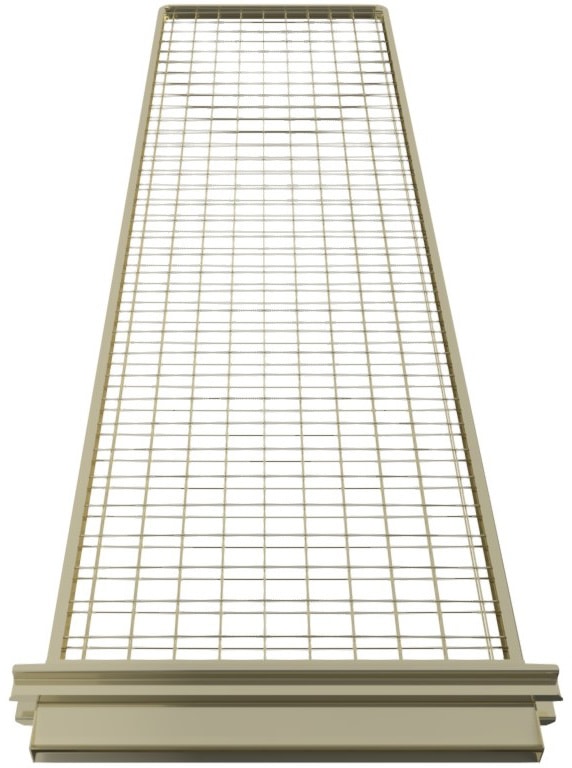

Multiple-filter bags | Support cages

We supply multiple-filter bags in polyester, polypropylene, polyacrylonitrile, polyamide P84, aramid and in the following special finishes:

- Silicone (water repellent)

- Teflon

- Carbon (spark resistant, spark protection shield)

- PTFE membrane

- Microfoam

- Stainless steel fibres

- Microfibres

- Oil and water repellent

- Flame protection / flame retardant

- Antistatic protection

We will also be happy to supply the corresponding spiral netting support frames of the desired size and quality.

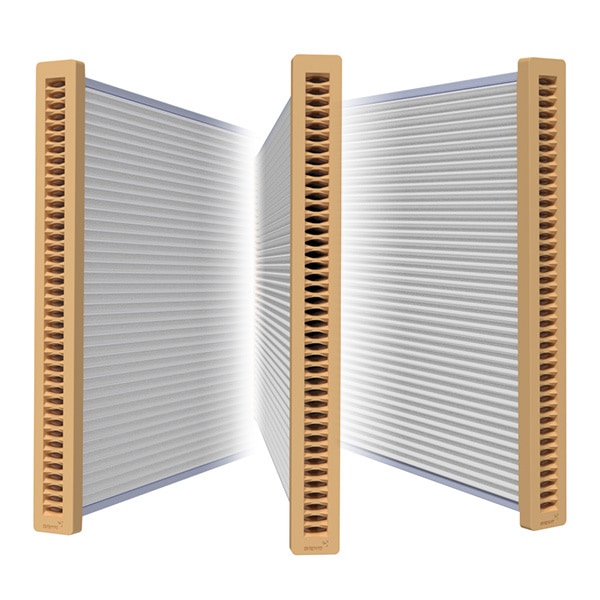

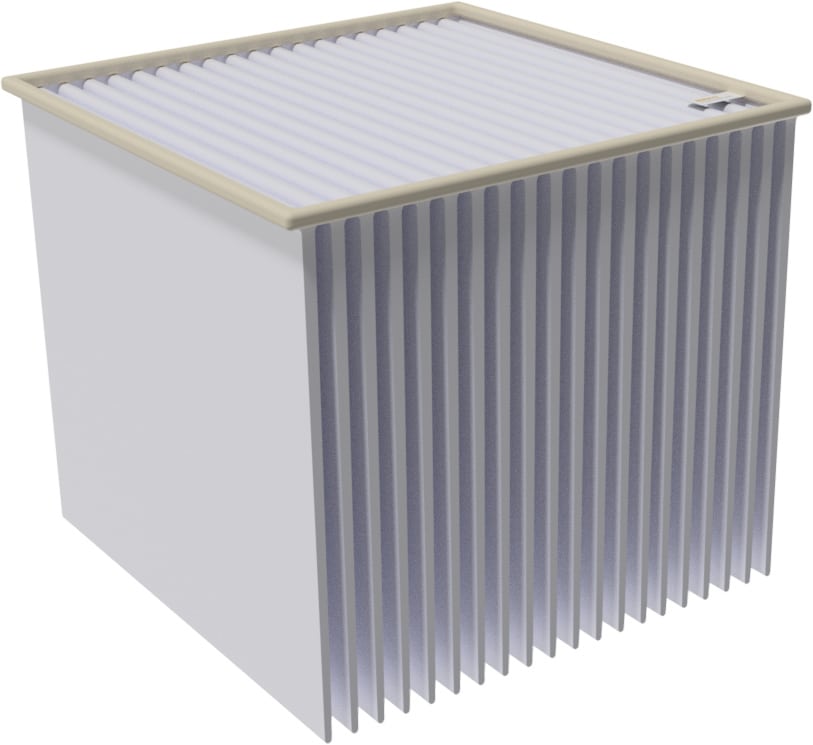

Filter cartridges

The filter cartridges we use are especially effective due to their large filter area contained within a compact space. They are available in the following designs and configurations:

- Conical

- Cylindrical

- Polyester fleece (hydrophobic / oleophobic, oil, dirt and damp repellent, antistatic, PTFE, ePTFE membrane etc.)

- Polypropylene fleece

- Polyester needle felt with food-safe certification, certified in accordance with EU and US FDA norms

- Cellulose fleece with nanofibers

- Aramid needle felt

- Stainless steel weave

- Plastic base unit, galvanized standard steel, stainless steel

- Threaded fittings

- Incremental intake

- Bayonet lock

- Tension anchor

- 3-hook flange

- Untreated gas side installation

- Purified gas side installation

- Venturi nozzle

- Dedusting nozzle

- Rotating air nozzle

- Displacement pin

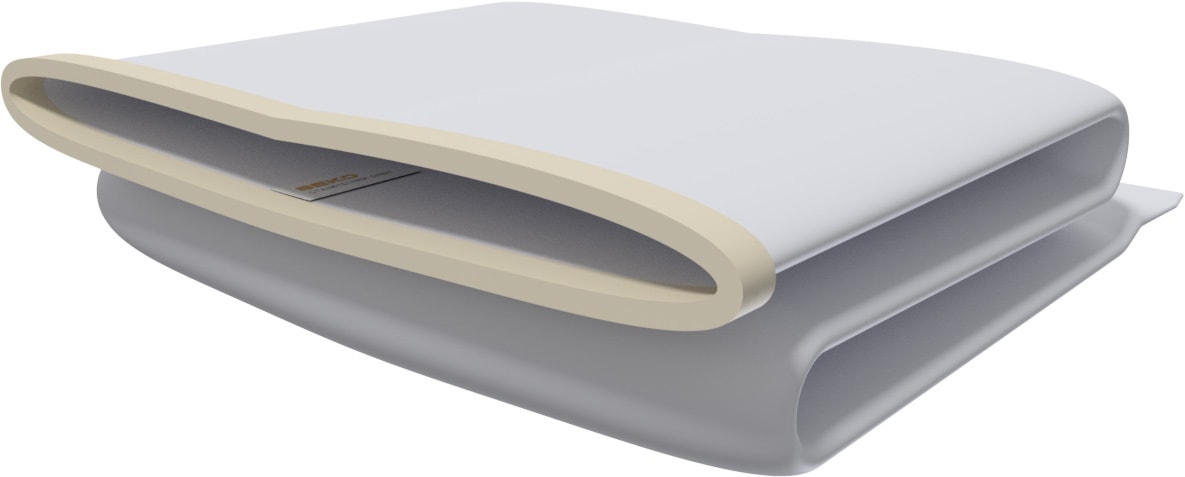

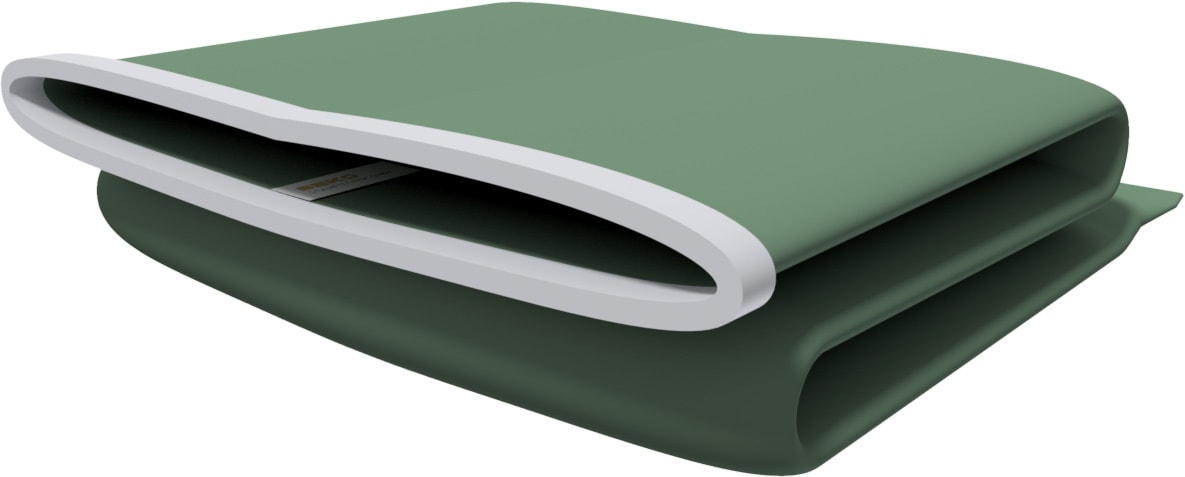

Compact filter elements

Our compact filter elements with venturi-shaped tips provide a large filter area within a compact space.These elements are available in a range of measurements and in the following versions:

- Microtex | Polyester

- Microtex A | Polyester oil and water repellent, antistatic

- Puretex | ePTFE membrane

- Toughtex | Antistatic polyester

- Flame retardant design

- Micro-porous coating

- IFA classes L, M, H

- Filter class DIN EN 779 for large and small dust particles

- Filter class in accordance with EN 1882-1 to H13

Valves

The valves we use guarantee a reduction in compressed air consumption of up to 20% and therefore contribute to a significant increase in energy efficiency.

We combine a flow-optimized construction with a high pressure impulse. The specially developed membrane is notable for its very brief pressure increase and automated shut-off function.

The dust removal efficiency of our valves at around 4.5 bar is equivalent to that of around 6 bar for our competitors’ conventional valves. This saves money with each pulse of compressed air and also helps reduce your environmental impact.

Filter control

SEKO filter monitors are designed to control 24 VDC magnetic valves in filter plants with compressed air jet cleaning systems.

Once the power supply voltage has been connected, the filter control operates fully automatically without further intervention. The differential pressure controller displays the current differential pressure of the filter equipment as a text display. The dust extraction is regulated by two independently configurable Δp switches. It starts up when a value of Δp MAX has been reached. All the connected magnetic valves are controlled by the previously programmed pulse duration and interval time values, beginning with the interval time. Once the differential pressure has reached the Δp MIN value, the dust extraction process shuts off.

For more complex challenges, we can also offer:

- Compact control cabinets with client-specific controls

- Customised control cabinets

- PLC control cabinets

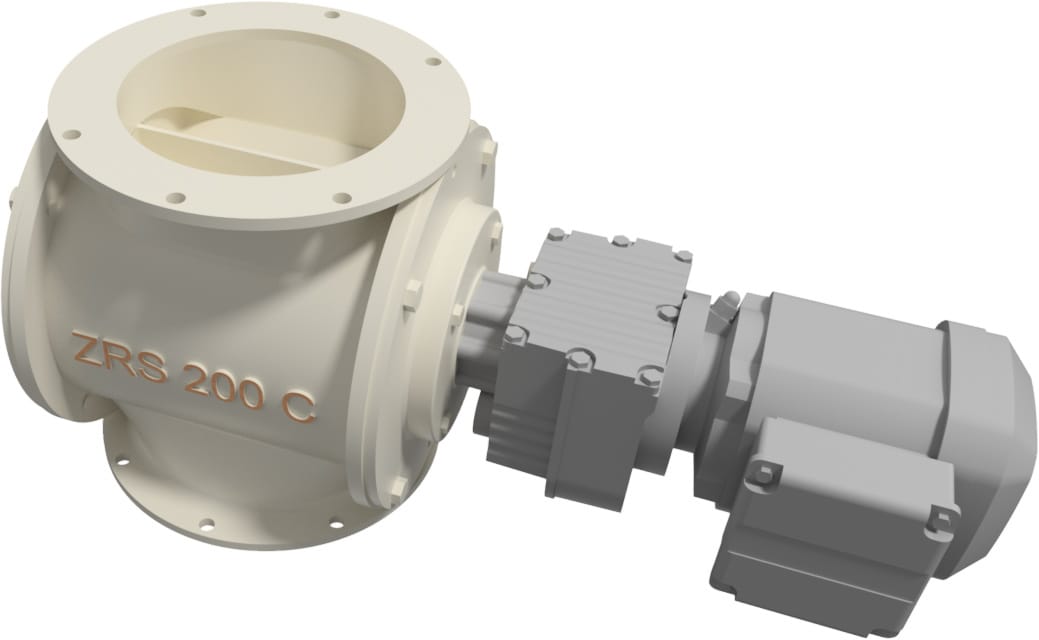

Discharge elements

Discharged dust particles are either returned to the production process or disposed of through a variety of discharge elements.

These include:

- Rotary valves with and without rapid extraction, also available in ATEX configuration

- Discharge screw conveyor, also available in ATEX configuration

- Chain conveyor

- Scraper conveyor

- Double dump valves in weight operated or motorized configurations

- Slider in manual or automatic configuration

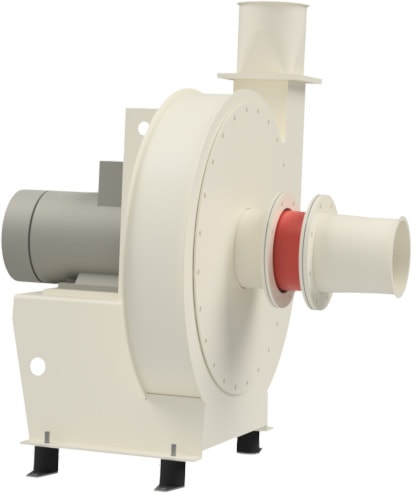

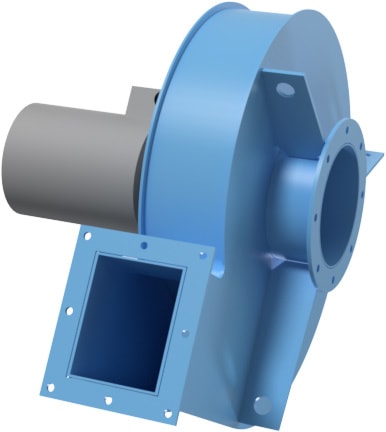

Fans

In order to guarantee a faultless dust extraction or pneumatic conveyance process, we use the following types of fans, according to needs. These are also available in ATEX configuration.

- Fans

- Rotary fans

- Side channel blower

These can be equipped with the desired final varnish, silencers, compensators, insulation, etc.